Halton’s Industrial Past

Halton Mills circa 1936

Halton has been the site of industry powered by the River Lune since at least 1252, when the lord of the manor of Halton was recorded as owning ‘two water corn mills worth forty shillings yearly’. There is also record in the same year of there being a water powered fulling mill (the earliest mills used for the production of textiles).

During the Industrial Revolution a series of mills for cotton, silk and oil cloth were built extending from Forge Weir to the lower weir, opposite Halton Railway station. By 1870 there were six water wheels and four additional turbines.

At some point in the early 20th century there was a turbine generating electricity on Forge Weir, with a ‘battery house’ (now known as ‘the Forge’) storing electricity for times when the water flow was too low. Water power continued to be used until 1960, when the mills ceased operation.

Halton Mill, the village’s last remaining mill building, will use electricity from the hydro scheme, so continuing the long tradition of water powered industry in the area.

Renewable hydro generated energy

The UK Government set a target in 2009 to generate 30% of electricity from renewable resources by 2020. Although much of this will be from wind power, they acknowledge that hydro, wave and tidal power will also play an important role. To encourage this development they introduced a Feed in Tariff (FIT) to ensure that schemes are financially viable. The FIT is guaranteed for 20 years and increases in line with inflation.

There are a number of ‘community hydro’ schemes in the UK that are already operating or currently being built using the same funding model as Halton Lune Hydro, including Stockport, Abingdon and New Mills in Derbyshire.

Halton Lune Hydro will, on average, generate more than 1,000 MWh of electricity every year – equivalent to the consumption of 300 average homes, although this varies depending on the average house consumption used, time of day and time of the year. This will enable CO2 savings of around 575 tons annually.

Halton Lune Hydro Ltd

Halton Lune Hydro (HLH) is a ‘Society for the Benefit of the Community (Bencom), which is a form of Industrial Provident Society, registered with the Financial Conduct Authority. The registered objective of the Society is to “carry on any business for the benefit of the community in and around the parish of Halton with Aughton by developing and operating community renewable energy projects”.

In 2008, Halton Community Association commissioned a feasibility study for a new hydro at Forge Weir and set up Halton Lune Hydro (HLH) to develop the project. Halton Carbon Postive was formed to obtain grant funding. HLH commissioned design studies and gained planning permission and, by mid December 2013, had received the necessary permits from the Environment Agency. HLH has leased the land on which the hydro will be built from United Utilities, who are pleased to have this project in their portfolio.

HLH has responsibility for design, procurement, construction and operation of the hydro, with support from hydro consulting engineers Hydro Survey of Kendal, Fishtek in Devon and Encraft of Leamington Spa.

There has been welcome support by a number of organisations including Lancaster City Council, The Department of Energy & Climate Change (DECC) and The Department for Environment, Food & Rural Affairs (Defra). The Environment Agency (EA) have dedicated a great deal of expert time to ensuring that all matters within their scope have been fully addressed. Once the hydro is operating, the EA will work with HLH on routine fish counting and specialist sampling.

The first stage of the project started in mid December 2013. The environmental works include river bank protection, fish screens and best practice fish and eel/elver passes. This work is funded mostly by a grant from the Rural Communities Challenge Fund, administered by Defra.

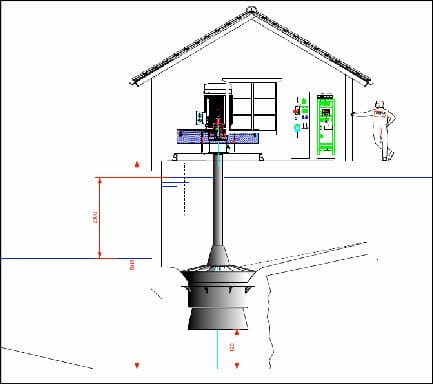

Following this, the first 100 kW Kaplin turbine will be installed. This is expected to be operational by Autumn 2014. A second turbine is scheduled to be added once the first has operated successfully for 12 months. This turbine will be eligible for the rate of Feed in Tariff prevailing at that time.

The hydro will use only a small part of the flow of the river at the weir (12m3/s maximum compared to an average of 34m3/s that often rises to 350m3/s). The water used reduces as river flow reduces, to the point of one or both turbines shutting down, to ensure that the weir and fish passes always have adequate flow of 4.7m3/s.

The River Lune is one of four UK Index rivers for Salmon and Sea Trout and so fish counting, trapping and restocking has happened for many years.

HLH fishery specialists have undertaken extensive analysis of ten years of Environment Agency (EA) monitoring data. They have worked with the EA to put together a package of work that not only improves fish passage over Forge Weir in both directions but also supplements the EA’s current work with a new fish counter and trapping/sampling facility.

We believe the improvements made will help reduce the current decline in fish stocks, noticed especially through 2013.